The future of municipal waste management? It’s not landfilling or incineration, it’s gasification. Here’s an excellent 16 minute overview by CNBC.

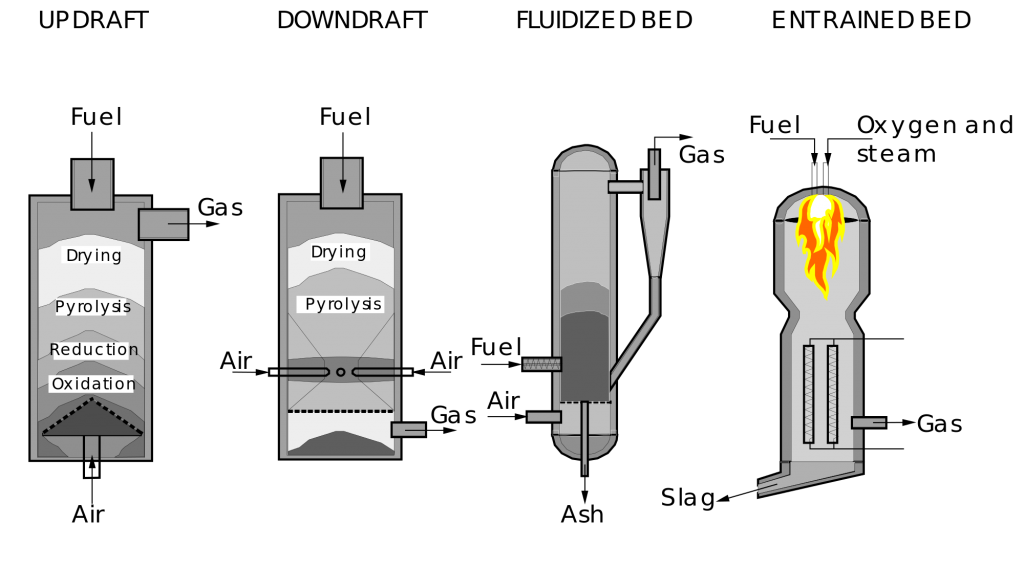

The 4 basic gasifier designs. Click the pic for info about this image.

New, dynamic gasifier designs for safely and efficiently processing large volumes of heterogeneous carbon feedstocks such as municipal solid and liquid wastes include the rotary gasifier (or rotary kiln) configuration. More information here.

Gasification

Gasification was first developed in the 1800s and has been used commercially throughout the world for over a century. Today, the majority of operating gasification plants produce chemicals, fuels, electricity, and fertilizers. Here’s a map of known gasification projects worldwide.

The most common scientific misconception of gasification is the assertion that “gasification is just another form of incineration.” Modern gasifiers do not have smokestacks, while all incinerators have stacks to vent combustion emissions. There are over 30 different makes and models of gasifiers available for a wide range of applications, ranging from pyrolysis (or partial gasification) designs used to convert biomass into biochar or convert shredded tires into synthetic diesel fuel, to extra-clean smokestack-free gasifiers that cleanly gasify coal, municipal solid/liquid wastes, hazardous wastes, and sewer sludges.to produce intermediate synthetic gas, usually referred to as syngas, which is composed of carbon monoxide and hydrogen (CO, H2). There are significant differences in the various gasifier designs, emissions and range of feedstocks, as well as scalability considerations and the volume quality of the syngas produced.

While incineration and gasification technologies may seem similar, the energy resource from incineration of feedstocks is open combustion and high-temperature heat, whereas the main energy resource from gasification is intermediate synthetic gas composed of carbon monoxide and hydrogen (CO, H2) which can either be combusted to produce electric power or cleanly converted via gas-to-liquid (GTL) catalysis or syngas fermentation processes to liquid fuels and a variety of chemical compounds.

Synthesis gas (CO + H2) conversion is the core process in the reformation of municipal solid and liquid wastes, coal and biomass into fuel and biochemical products. In gasification either a single feedstock or multiple feedstocks are converted by high temperature and conversion conditions are carefully controlled so that prior to exit, nearly all carbon content is converted to CO and H2 syngas.

Non-carbonaceous materials which are not converted into syngas, such as metals, glass, rock, sand, dirt and concrete, are slagged out, either as ash, or as a molten pour of obsidian-like, inert vitreous glassy slag, depending on the gasifier design. The ash is considered toxic waste and must be landfilled. Slag can be safely landfilled as it will never leach, however the material also has many commercial uses as an abrasive element, building materials or road base.

A number of factors contribute to growing interest in gasification, including solid and liquid waste proliferation, climate change concerns, rising environmental pollution, volatile oil and natural gas prices, less stringent environmental regulations, and a growing consensus that more efficient CO2 management should be required in power generation and liquid fuel production, as well as traditional waste disposal methods.

More info about gasification: Gasification Technologies Council: Gasification: An Investment In Our Energy Future (PDF)

More info about Syngas: Gasification Technologies Council: Gasification: The Waste And Energy Solution (PDF)

Incineration

Large or small, all waste incinerators have smokestacks.

Incineration is the waste management industry’s current solution for converting municipal solid waste into electricity, heat, metals recovery and other value added products. Virtually all current waste-to-energy facilities are incinerators. There are estimated to be over 450 operating incinerators in western Europe, while the U.S. EPA estimates that there are currently approximately 176 industrial waste incineration units operating in the U.S., including incinerators, small remote incinerators, burn-off ovens, waste-burning cement kilns and energy recovery units.*

* Source: U.S. EPA. “Standards of Performance for New Stationary Sources and Emission Guidelines for Existing Sources: Commercial and Industrial Solid Waste Incineration Units, Proposed Rule.”

Incinerators must vent byproducts of combustion (C02, H20, CO, NOx, SOx, microscopic particulates, etc.) in order to function. An incinerator is essentially a box connected to a smokestack with a fire at the bottom and scrubbers at the top to extract the worst pollutants but send the rest of the particulates and greenhouse gases to the atmosphere. In incineration, excess O2 is added to the input waste so that at low temperature it burns. The result is heat and an exhaust of CO2, H2O and other byproducts of oxidation combustion or partial combustion, including poisonous dioxins and furans. According to US EPA data, trash incineration releases 5,511 pounds of carbon dioxide per megawatt hour of energy produced, or about 2.5 times more than the 2,186 pounds to produce the same amount of energy from coal. As much as 30% of the processed solid waste remains as ash. This ash is typically categorized as hazardous solid waste.

Hidden emissions: A story from the Netherlands Case Study, Zero Waste Europe (PDF)

Bottom Line

Gasification is inherently superior technology for converting all types of solid and liquid wastes and fossil feedstocks to clean, intermediate syngas, which can then be converted to electric power and/or liquid fuels, without emitting toxic compounds or CO2 or requiring supplementary fossil fuel. Gasification technologies in combination with steam-driven Gas to Liquid (GTL) fuel synthesis architecture represent the future of environmentally responsible municipal waste management and extra-profitable liquid fuel production.

Rotary kiln photo:

Rotary kiln photo: